Solution

We will fully knowledge your needs and provide with the perfect solution (whether it is a complex structure or a special function).

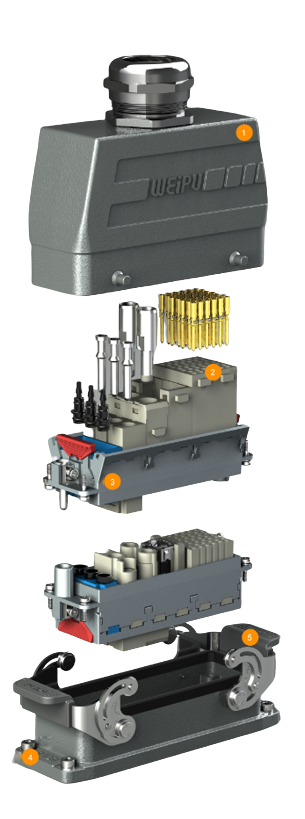

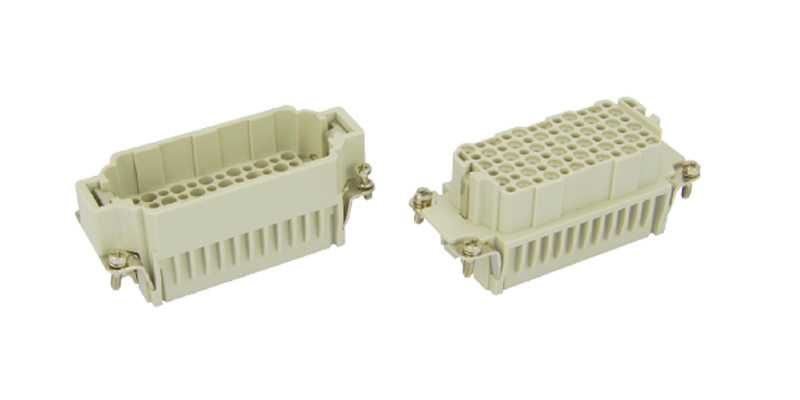

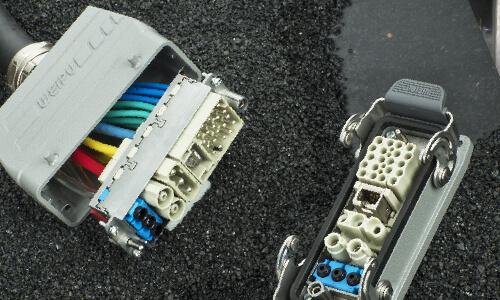

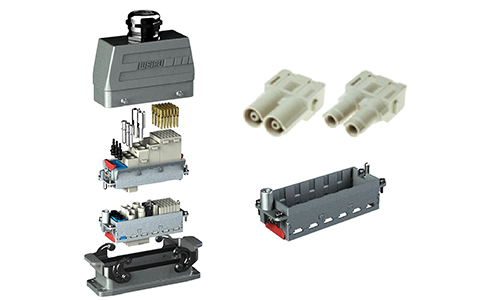

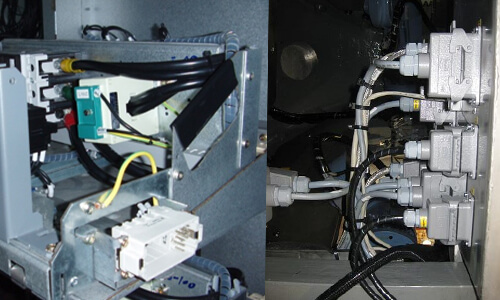

Heavy-duty connectors are mainly used for electrical or signal connections between different devices or functional units, which provide great convenience for the installation and maintenance of complex control devices. Heavy duty connectors are widely used in rail transit, industrial automation, mechanical equipment, electric locomotives and petrochemical electric power, etc. . They are standard electrical connection components for Industry 4.0.

Your Expert Heavy Duty Connector Supplier

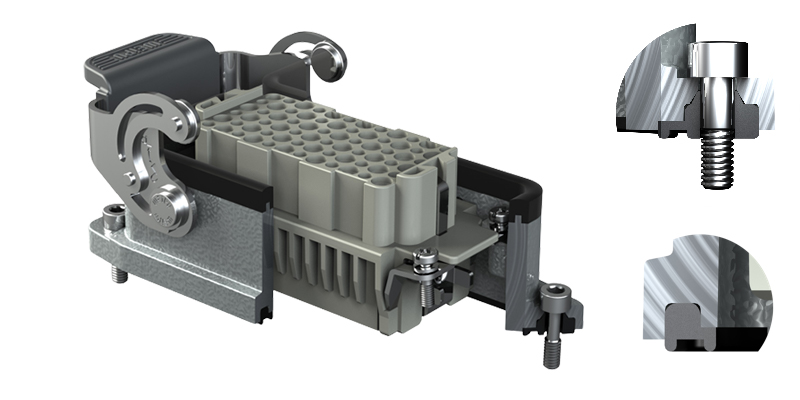

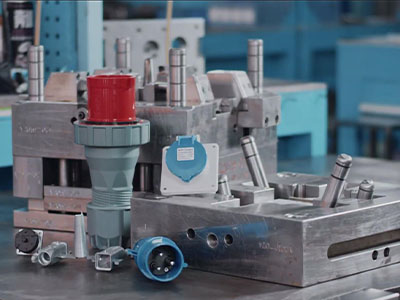

Design Standards of heavy duty connectors including IEC 61984、IEC60664-1、IEC60352、IEC60529、EN 175301-801. Heavy duty connector housings are made of cast aluminum or flame retardant thermoplastic materials and are powder coated to withstand impact and mechanical pressure. SEALANT gasket between housing.The fire rating is V-0, which the product is IP65.

The IP65 metal housing has successfully passed the IP67 test and is more robust and waterproof, more resistant to applications that meet harsh environmental conditions.

We use famous brand equipment, guarantee the product stability. Production process is fully automated, to reduce the error of operation, ensure the product quality and production efficiency.

Your Expert Industrial Connector Supplier

WPCONNECTOR have 26 years heavy duty connector manufacturing experience withfull set equitment and more 500 skilled workers,can products more tougher, stronger, and more resistant heavy duty connector than other competivitor in more faster delivery speed.

WPCONNECTOR heavy connector manufacturing capabilities base on each production step finish in house workshope,include mold,die casting,plastic injection,plating, assembly and testing;and the test results of each production step is retained and traceable,all those make the top quality connector.

WPCONNECTOR products heavy duty connector in same quality as word famous brand,but price less that half,because of the strict production management processes and benefit of Made in China to reduce cost.

Certificated by EN/IEC 61984,CE,UL and CSA,trust by ABB, Bosch, KUKA, Foxconn, Midea etc.

For the last decades, we obtained 100+ innovative valuable patents, exported to 40+ Countries, and offer 100+ successful projects, such as Beijing Bird’s Nest Stadium, Oriental Art Center, Shanghai Hongqiao Airport Terminal 2,etc.

And We serve many famous brands, such as COUNTRY GARDEN, KUKA, MIDEA, ABB, BOSCH, SAMSUNG, FOXCONN, etc..

Get in contact with one of our representatives today.